TomTerritory

Member-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Articles

Media Demo

Everything posted by TomTerritory

-

Aftermarket headunit, reverse sensor beeps

TomTerritory replied to TomTerritory's topic in Audio/Visual Workshop

Thinking about wiring both outputs (standard unit and new unit) to the front speakers using this method https://www.epanorama.net/circuits/linesum.html -

Aftermarket headunit, reverse sensor beeps

TomTerritory replied to TomTerritory's topic in Audio/Visual Workshop

Sounds like a good work around! So if I use a line converter I can then have an rca to 3.5mm audio jack cable into the front of the new head unit. -

If I install an aftermarket head unit (single din in the tissue box) will I lose the reverse sensor beeps? I do love those beeps..

-

Tried bypassing the solenoid and no difference hit 19-20psi..., so im thinking.... do I try and fix the wastegate to get control of the boost, either by new housing (eg plasmaman), send the housing to someone else to port it for me or go external gate.... Or do I just go for 1000cc injectors and new fuel pump and go for all the boost.... Not sure if this is a good idea with stock top mount though. and I guess I will have to do valve springs too.

-

Update, got it tuned. They couldnt control the boost below 16psi 😭 So they set the rev limter to 5,200rpm as they were running out of fuel to tune it at that psi. Still it made 248kW @ 5,200rpm. The tuner was a local tuner who has pcmtec and an awd dyno. Not sure why they didnt try this but I am going to try and bypass the boost control solenoid and see if that's causing overboost. Otherwise my porting job was no good...

-

Nevermind… dumb idea it runs out of stroke at 10psi so I would just be limiting how much it opens! Actually surprised at how little it opens. this is what I measured for pressure Vs travel for reference. 0psi = 0mm 4psi = 4mm 6psi = 10-11mm 8psi = 17-18mm

-

Next question, how much pre-load should I set the actuator up with? I dummy set the arm up with a bit over 1/2 a hole and put pressure on the actuator (co2..) and the hole lines up at ~4psi, so the actuator begins to open around 4psi. Shall I pre-load it a bit higher ~ 6-8psi. Will that make it easier to control boost a bit higher?

-

-

Whoops, had it scheduled. Fixed it

-

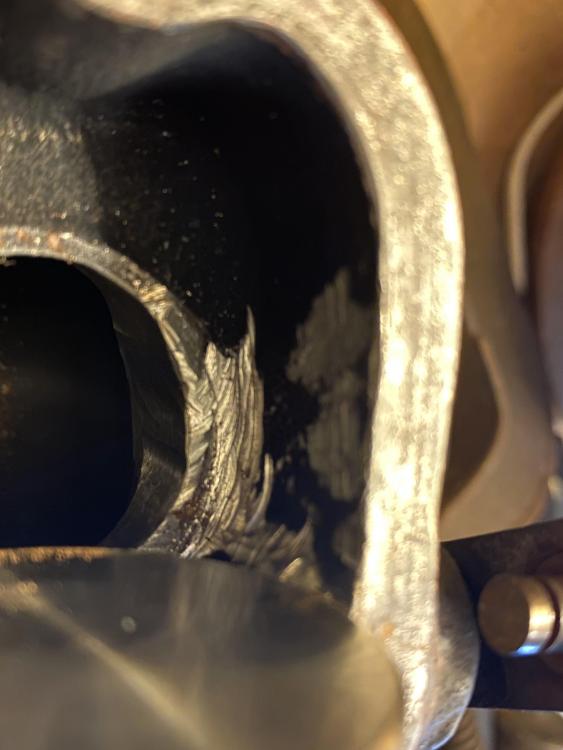

Its a bit of a botched job really, not too keen on posting pics and getting flamed for it! Anyway see image, please be kind... While grinding the housing I marked up the sealing surface. Got me a bit annoyed, I was rushing a bit as I had a good welder lined up to do the weld for me that night. Thinking about pulling the actuator arm out and taking it into work and getting the face milled to clean up the surface. Testing with light it doesnt look too bad though, but obviously not perfect. See short vid of me testing it with light. https://youtube.com/shorts/P1_fapaKPCI?feature=share

-

Just wondering if anyone has any experience with these housings? I assume they’re Chinese, are they good quality cast & machine finish? https://plazmaman.com/product/ford-barra-1-06-rear-turbine-housing-40mm-flapper/

-

yeah realise this now. Did not think I had to with the 37mm flapper. I’ve ground it out now and it seems to seal ok. Albeit not perfect. Slight bit of light coming out but better than before.

-

I’m just about giving up on this and looking at buying a new housing. Carefully ground off the old flapper, put the new 37mm flapper in and it catches on the side of the housing? It’s too big.

-

Yep ordered one today. Paid a bit more than that though through mtq. Just wanted to get it tomorrow so I can get it sorted over the weekend!

-

Think I need to get the larger flapper, I ground it out slightly too large on one spot. Looked ok, then I shone a light through and can see light coming out in one section. Tested with feeler gauge and its about 0.2 - 0.25mm gap on about 10mm of the circumference. Guessing this will affect spool up if its not fully sealed. Thinking I need to get the 37mm flapper now.

-

Wow, looks good. So to change the flapper you grind it off and weld the new one on?

-

Porting progress… not sure how far to go, don’t want to go too far. drilled that fitting out too…

-

So the 1mm restriction could’ve been causing issues? Shall I bore it out?

-

Pulled the turbo off today, I’m still concerned about the amount of shaft play. I had a look at the new oil feed fitting to the turbo and it has approx 1mm bore hole in the end! It’s full bore hole on the tapered end but on the other end is restricted. I feel like this is a machining error?ill try and upload some photos

-

Yep I understand. Been watching a few youtube videos!

-

Thanks again guys. Really appreciate your replies! Going into lockdown tonight so might have a go at the flapper mod over the next week.

-

there doesn’t seem to be any in out play

-

I’m back to stressing out that the turbo is stuffed. I know puff you said the noise sounded ok but I feel like there is a fair bit of play in it too. Also the noise. It made zero noise before installing it and zero play. Only been on the car a couple of weeks. im going to pull the filter off tomorrow and have a look. Mechanic said they checked everything, oil supply and drain. note the old turbo oil feed line was clean and not blocked but the old turbo had gunk in it looked like blocking the channels internally? see video, I’m just wiggling the shaft up and down you can hear the play. I use a sock as it’s still hot I was just driving (would there be play when hot and not when cold?)

-

their concern was not being able to control the boost down low enough with the stock actuator not being able to flow enough air. I said it’s a stock dump pipe and seemed to run ok on the stock turbo with the flash tune…. Spoke to another tuner an hour away with an awd dyno and they do pcmtec they said I probably will be ok without flapper mod, thinking about going with them. Just a bit far away if I need a follow up tune etc.