-

Posts

103 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Articles

Media Demo

Everything posted by fastfwd

-

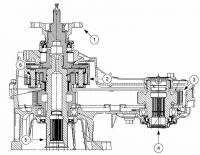

Found this diagram... Number 4 is where the shaft is going in... From pictures of the shaft it just looks like a gear.

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

Yeah I figured this. But as stated in pictures and said above I'm replacing the whole ball joint and arm itself. So I can hammer and damage the thread and ball as much as I want to remove it because I'm replacing the lot. Thanks for the concern though.

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

Couldn't pull the shaft out to look at the end.. Its to long it hits the hub before it can come out. Need to find someone that's worked on these... I think it would be something simple like putting it in neutral and lining it up some how or something along those lines... I've tried every combination I could think of.

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

I found yellow paint on both sides. Wasn't diffinative but it was all I could see... Tried a good 5 mins to try and line it up and push it in but no go. Any other ideas?

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

Nah didn't swap them they on the Same side. But I didn't check for a key. I did try and turn it all the way around and push it in to see if it only went in one way... I'll go check if it has a key now.

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

Ok so I got the ball joint out... The one from Repco didn't work but the fork from supercheap did the trick.. I did hammer on the side as you had said about but that didn't work either... Anyways it's out... But now I have another problem I don't know how to solve. The inner Cv joint shaft has come out of the gearbox or what looks like a gearbox maybe a transfer case on the awd. Anyways it's come out and the damn thing wont slot back on... Any idea's... Here is a vid of it. http://youtu.be/EW5_gMPTZjs

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

this one http://www.supercheapauto.com.au/online-store/products/Stanley-Ball-Joint-Separator-Mini.aspx?pid=105533#Recommendations or this one? http://repcoequipment.businesscatalyst.com/repco/repco-ball-joint-separator

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

Tried everything today...hammering the sh*t out of it. Tried to vice grip onto the ball end and twist it, the end of the tread has a 10mm socked end on it so I tried turning it. Nothing worked so I just ended up hammering the crap out of it but still no go. Unsure if I can get a 10mm onto it anymore cos ive bent the crap out of the end of the thread. I still dont thing it threads onto the hub, it makes no sense to do that I just think its stuck inside it some how. any idea's?

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

Hi all, Other day at the servo in my territory ghia turbo the ball joint on the LCA just crapped itself and popped out. Tow truck driver said its common problem on these cars. I had trouble getting parts over xmas but I made it happen so I got all the parts and im working on it today and the ball joint that goes into the rear section of the hub is stuck. Does anyone know if this is threaded or just a shaft. The damn thing just wont come out. Pictures below of the new arm, old arm and ball joint stuck in the hub.

- 15 replies

-

- ball joint

- LCA

-

(and 1 more)

Tagged with:

-

It felt really light in my hand. I havent felt the standard so I couldn't really compare. In their website they have exact weight of the standard and the weight of the 11 blade and it's 13 percent lighter. It's currently in the car running. Sounds bloody nice. Car isnt fully tuned. Competing 3inch to 4 inch intake upgrade especially when I have . 70 ar housing and a dual 3.5 cat upgrade. Then running the full tune... Simon from extreme ford recommended those upgrades before completing the proper tune. The spool sounds so much deeper than previous. Probably the . 70 ar housing.

-

Yeah was like I thought pressure sensor. Don't know but there must not been something wrong with the hose I used. Got it working. Cleared the limp mode and reset and all good

-

Thanks mats Anyone know what this code is referring to? Need to find what sensor this is.

-

Ok found it and did a "read dct's" under check engine settings. I figured day's were the sensors. This it the error. Is this the pressure sensor?

-

I have different injectors but I didnt change them this time round. Was done on a previous tune.

-

Hi all, I have recently replaced the turbo, new front mount, new piping. Basically had most of the induction and exhaust apart. I have put the car back together and its running but it goes into limp mode. Car wont throttle over 2-3000RPM, I figured I forgot to plug in a sensor. Went over all of the sensors and made sure they are plugged in correctly. All look fine. I have a SCT Chip with hand controller. Tried looking for the ecu to plug the hand controller into see if it has a diagnosis function to see what sensor is the issue but I couldnt find the ECU. Does the hand controllers have diagnosis settings? what would be the easiest way to diagnose this. Got a tune in the morning and need to sort it out before then. :(

-

Put it this way... I got my $1000 plazmaman cooler which was second hand unused for $150. I already had the plates of metal from some old off cuts so that was free. it took me around 1 hour to cut/paint and an engineers certification which if he approves straight up will only cost me $150. If I have to edit it and come back then it will cost me an extra $150. So at this moment best case scenario I will have only spent $300 completely certified, included in the certification is the front mount itself. I don't feel any of this is a waste of time or money thus far. Not trying to insult you but this "getting a bigger cooler" to solve the issue is neanderthal approach to the solution. Because people are scared to touch the crumple bar doesn't mean it cant be done safely and legally.

-

Yes it did, nissan 200sx s15 - both passenger and driver, both of them blew on impact, my face can tell you that. Hurts....

-

No I am cutting a portion of the bumper out that goes right over it, highlighted below. I will chuck some mesh gridded mesh similar style to the one around the ford badge and paint it black. I understand it will perform better, but im not after better, im after best. I want to optimize as much of the the mods I make as possible. why is everyone a h8er? If it can be done safely and legally then all benefits to me for getting the most out of a front mount possible. Its not as expensive as people think to get an engineers assessment/certification and it didn't take me that long to complete, probably took me an hour to cut and paint. If I had a dyno in my back pocket I would complete a first test on it without the mods to the bar and the bumper then complete a second with the same setup to see the difference in heat soak on the cooler. Then I would complete the same 2 tests on it with the bumper and bar modded. I could never guarantee that it would or wouldn't make a difference if these tests weren't done but considering the way a intercooler works more flow across it = better.

-

I dont know if they are just helping me out with that pricing because they do owe me quite a few favors.

-

I completely understand all of your concerns. Cutting the bar does sound stupid and maybe classed as car taboo. But I didn't just cut it willy nilly without prior knowledge. I opened this tread to get idea's because I didn't want to cut the bar if others had done something different with airflow by getting around it. But seeing as it seems like everyone just leaves the bar blocking 30-40% of the cooler, "buying a bigger one" seems like a slightly useless resolution. I know most people just do this but I don't really like that fix when I know other things can be done. I have completed this exact edit on a previous car. I brought it to an authorized engineer certified by Department of transport WA. He told me to have 3mm steel plates welded across the bar horizontally on each sized of the cuts to reinforce the changes. He signed off on the changes and gave me a certification, this cost me $150 for certification. In this car I also was involved in a T bone crash which wasn't my fault. My car went directly into the side of another car what didnt give way. My car was a complete write off and the HBF claims investigator did ask about the changes made a week lster and I showed him the certification and he approved it. I was paid out for my write off without issues. I will be taking my territory to the same engineer, I have already welded the steel plates across the modifications, the same as last time. If he feels that the modification isn't structurally sound even with the welded plates then I will weld the originals back into place as they came (this is why I don't want to cut the whole thing off as this is stupid plus it is unsafe). I do want to keep my car legal and safe. taking it to an engineer for approval will give me this piece of mind and will also give Department of Transport authorization if anything happens.

-

I have welded some thick plates on each side of it, taking it to an engineer next week to get certified so I don't have that problem.

-

Install Wheel, Compressor housing, Supply Compressor housing fittings, Flapper mod edit, and Wheel balance. $530.

-

It's stage two rated at 800hp. Plasmaman. Big enough.. I still wanted to keep. Some safety aspect And yes it's in my TT which has that perfect grill that can be cleanly cut out and have some after market mesh of some sort. All black along with the car so it's all hidden.

-

Mtq has my turbo atm and they called me telling me that a rebuild was done but not genuine internal bearings. So had to fork out 900 to replace the core. I did end up getting $900 back off the seller. Still doesn't cut my losses. Should have just rebuild my own turbo